CAPABILITIES

CAD and CAM Programming Services

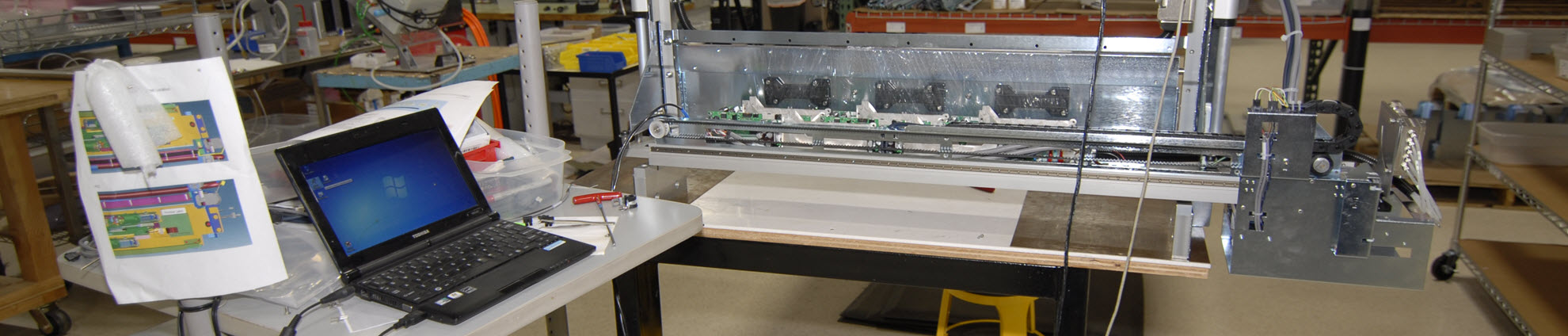

In CAD/CAM (Computer Aided Design/Computer Aided Manufacturing), products are designed using computers. This is a generic term used for a number of technologies, such as computer modeling and design software, rapid prototyping, and computer numerical control. BDE Inc. utilizes CAD/CAM design and programming services to optimize its in-house manufacturing processes.

Features of CAD and CAM Programming Services at BDE Inc.

BDE Inc. employs CAD/CAM programming services primarily to enhance the efficiency and precision of our CNC machining and tool-making solutions. While our focus is on internal operations, we understand the interest in these services from external customers. However, we are not offering these services to external customers due to liability considerations associated with programming for third-party machinery. The following key features define our CAD and CAM programming services.

1. Project Planning: Our teams work collaboratively to ensure seamless coordination, meeting deadlines, budgets, and specifications. We maintain open communication and provide regular project updates to keep all stakeholders informed.

2. Comprehensive Design and Documentation: We develop tool and fixture designs tailored to our manufacturing needs. Our designs and fixtures are archived for future reference, and we document programs to support repeat orders if needed.

3. Advanced CAD Modeling and Simulation: We utilize state-of-the-art CAD software to create detailed 2D and 3D models, conduct simulations, and refine designs before manufacturing begins.

4. Precision CAM Programming: Our team programs CNC machines using advanced CAM software, ensuring efficient tool paths, material optimization, and high-precision machining results.

5. Integration with Best-in-Class Tools: We maintain strong relationships with reliable tool manufacturers, enabling us to use premium tools, tool holders, and work-holding solutions for our machining setups.

6. Quality Assurance and Process Optimization: We implement rigorous quality checks throughout the programming and manufacturing process, ensuring accuracy, efficiency, and continuous process improvement.

Outstanding CAD/CAM Programming Services – Building the Right Foundation

In the initial phases of a project, we utilize cutting-edge technologies and methods such as mock-ups, CAD drawings, and 3-D solid modeling. Throughout the different stages of development, we incorporate computer-aided manufacturing, production techniques, materials selection, and application-specific methodologies. Our specialized approach enhances manufacturing efficiency and supports the production of high-quality components for diverse industries.

BDE Manufacturing Technologies was honored by Modern Machine Shop in an article highlighting Top Shops 2011: Bob’s Design Engineering, Inc.

At BDE Inc., our team of experts brings a lifetime of experience in CAD/CAM programming to optimize in-house manufacturing operations. Having served industries such as semiconductors, marine, food, aerospace, military, and medical, we possess deep industry knowledge and expertise. For any other machining and manufacturing needs, please feel free to reach out to us at 866.262.6233 or email us at info@bdeinc.com.

BDE Inc. offers CAD/CAM programming services solely for internal manufacturing and does not provide them for third-party use.

Related Blog Post:

Why First Time Customers Should Consider CAD/CAM Manufacturing

CAD CAM Programming Services Specifications

|

|

|---|---|

| General Capabilities | Consulting Design Prototyping Research & Development Tooling Design |

| Industry Focus | High-Tech Energy Electronics Aerospace Medical Printing Semiconductor |

| Industry Standards | ANSI – American National Standards Institute ASME – American Society of Mechanical Engineers ASTM – American Society for Testing and Materials ISO – International Organization for Standardization Mil-Spec – Military Specifications RoHS (Compliant) – Restriction of Hazardous Substances |

| Design & Drafting | 3-D Modeling CAD Drawings Mock-Ups |

| Manufacturing Disciplines | Assemblies Computer Aided Manufacturing Hydraulics Mechanical |

| Industrial Procedures | Manufacturing Production |

| Manufacturing Process | Applications Materials Selection and Application |

| Product Design | Cameras Industrial Printers |

| Additional Services Provided | CNC Machining EDM Machining Prototype Machining |

| File Formats | 3D ACIS Model File AutoCAD (DWG,DXF) BMP DXF GIF IGES Inventor (IDW, IPT) IronCAD (ICD,ICS) JPG or JPEG MasterCam (MDX, MC8, MC9, SET) Pro-E or Pro/Engineer (DRW,PRT,XPR) SAT SolidWorks (SLDPRT,SLDDRW,SLDDRT) STEP TIFF |

Capabilities

|

|

|---|---|

| Equipment | 10 Seats of Mastercam 2017 CAM Software. 2 Seats of Autodesk Inventor 2016 Design Software. Cutting Edge Server and Networking Technologies. Intel based Multi-core Work Stations. |

info@bdeinc.com

info@bdeinc.com 866.262.6233

866.262.6233